- Oil-free Air Compressor

- Oil-free Air Blowers

- Scroll Air Compressor

- Air Compressor

- Stationary Air Compressor

- KAISHAN LG Series

- KAISHAN LG 2-stage

- KAISHAN LG Water-cooled

- Kaishan KSZJ diesel

- Boreas Screw Compressor

- Boreas BMVF Series

- KAITAIN JN Series

- KAITAIN JN 2-stager

- Kaitain JN Integrated

- Kaitain JN High Pressure

- Kaitain PMVF series

- Kaitain JN 0.3Mpa

- Kaitain JN 0.5Mpa

- Portable Air Compressor

- Kaishan KSCY diesel

- KAISHAN LGCY Diesel

- KAISHAN LGY Electrical

- KAISHAN LGCY 2 Stage compression Diesel

- KAISHAN KSDY Electrical

- KAISHAN ML Explosion-proof

- KAISHAN LGJY Mining

- KAISHAN LGN Series

- KAISHAN LGYT Mining

- Piston Air Compressor

- KAISHAN KA series

- KAISHAN KB Series

- KAISHAN KJ Series

- KAISHAN KS Series

- KAISHAN Mining Series

- Kaitec Screw Vacuum Pump

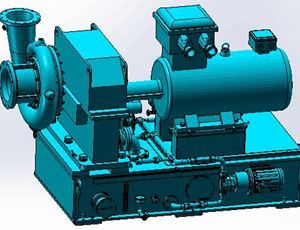

- High-speed Single-stage Centrifugal Blower

- Industrial Refrigeration Heat Pump Applied Screw Compressor

- Centrifugal Air Compressor

- Centrifugal Steam Compressor

- Centrifugal Refrigerating Compressor

- Gas Air Compressor

- ORC Screw Expansion Power Station

High-speed single-stage centrifugal blower adpots overall composition pry structure type. The main body of the compressor is composed of (IGV, diffuser, volute, moving parts, seals and other components), the growth rate of the gear box, the drive system (motor + coupling and guard), lubricating oil passage and docking system and other components. The centrifugal blower adpots design software by the world famous American company Agile CN professional turbomachinery , three-dimensional flow backward curved impeller industry experts and designed by the whole stick CFD analysis to ensure compressor high efficiency, wide range of operating conditions and other characteristics. The centrifugal blower also adopts international advanced rotor dynamics and bearing design software DyRoBeS, finite element analysis software design strength, stiffness, modal, thermal stress on the impeller and other core components of a comprehensive analysis to ensure long-term stable operation of the rotor.

According to customized design to ensure the highest point of each project are efficient.

Technical Parameters of High-speed Single-stage Centrifugal Blower

Main application industry |

Platform |

Model |

Flow m3/min |

Rated working station |

Compression ratio |

Industrial, sewage treatment |

1 |

KCA100-1.7 KCA150-1.9 |

80-125 |

Q=100m3/min Tin = 25°C |

1.7 ~1.9 |

2 |

KCA150-1.7 |

130 〜200 |

Q=150m3/min Tin = 25°C |

1.7 ~1.9 |

|

3 |

KCA250-1.7 |

205-320 |

Q=250m3/min Tin = 25°C |

1.7-1.9 |

|

4 |

KCA450-1.7 |

330〜520 |

Q=450m3/min Tin = 25°C |

1.7-1.9 |

|

5 |

KCA750-1.7 |

540-850 |

Q=750m3/min Tin = 25°C |

1.7 〜1.9 |

|

6 |

KCA1200-1.7 |

880 〜1400 |

Q=1200m3/min Tin = 25°C |

1.7 ~ 1.9 |

Main application industry |

Platform |

Model |

Flow m3/min |

Rated working station |

Compression ratio |

Power plant desulfated NOx |

la |

KCA100-2.9 |

80-125 |

Q=100m3/min Tin=25°C |

1.95-2.9 |

2a |

KCA150-2.9 |

130-200 |

Q=150m3/min Tin=25°C |

1.95〜2.9 |

|

3a |

KCA250-2.9 |

205-320 |

Q=250m3/min Tin=25°C |

1.95-2.9 |

|

4a |

KCA450-2.9 |

330-520 |

Q=450m3/min Tin=25°C |

1.95-2.9 |

|

5a |

KCA750-2.9 |

540-850 |

Q=750m3/min Tin=25°C |

1.95-2.9 |

|

6a |

KCA1200-2.9 |

880 ~ 1400 |

Q=1200m3/min Tin=25°C |

1.95-2.9 |

- Drill Rigs and Rock Drills

- TopHammer Drilling Rigs

- KL511 top hammer drilling rig

- KL510 top hammer drilling rig

- Tunneling jumbos(1 boom)

- KJ211 Tunneling jumbo

- KJ212 Tunneling jumbo

- KJ310 Tunneling jumbo

- KJ311 Tunneling jumbo

- KJ311 higher Tunneling jumbo

- KJ311 double Tunneling jumbo

- KJ311plateau Tunneling jumbo

- KJ311 Diesel Tunneling jumbo

- Face drill rigs(2 boom)

- KJ421 Tunneling jumbo

- KJ422 Tunneling jumbo

- Rock Bolting Rigs

- KM211 Rock Bolting Rig

- KM311 Rock Bolting Rig

- Tunneling DTH Rigs

- KS311 DTH Rig

- KSQ31 DTH Rig

- Tunneling Scaling Rigs

- KQ311 Scaling Rig

- Top Drive Drilling Rig

- KMD150 Anchoring Drill Rig

- Integrated DTH drilling rigs

- KT5C/YT5C DTH drilling rig

- KT6C DTH drilling rig

- KT7C DTH drilling rig

- KT9C DTH drilling rig

- ZT5 DTH drilling rig

- ZT10 DTH drilling rig

- KT11 DTH drilling rig

- KT12 DTH drilling rig

- KT15 DTH drilling rig

- KT20 DTH drilling rig

- KT25 DTH drilling rig

- KT30 DTH drilling rig

- KT20S DTH drilling rig

- RK60 DTH drilling rig

- Crawler DTH drilling rigs

- KG310 DTH drilling rig

- KG320 DTH drilling rig

- KG410 DTH drilling rig

- KG420 DTH drilling rig

- KG420S DTH drilling rig

- KG430 DTH drilling rig

- KG430S DTH drilling rig

- KG510 DTH drilling rig

- KG520 DTH drilling rig

- KG590 DTH drilling rig

- KG610 DTH drilling rig

- KG9 DTH drilling rig

- KG920BHIII DTH drilling rig

- KG726HIII DTH drilling rig

- KGH3AIII DTH drilling rig

- DTH Drilling rig

- Rock Drills and Jack Hammer

- Hand-held Rock Drill

- Air-leg Rock Drill

- Pneumatic Rock Drill

- Water Well Drilling Rig

- Crawler Water Well Drilling Rig

- Wagon Water Well Drilling rigs

- Core Drilling rigs

- Road Machinery

- Air Pick

- Auxiliary Equipment