- Oil-free Air Compressor

- Oil-free Air Blowers

- Scroll Air Compressor

- Air Compressor

- Stationary Air Compressor

- KAISHAN LG Series

- KAISHAN LG 2-stage

- KAISHAN LG Water-cooled

- Kaishan KSZJ diesel

- Boreas Screw Compressor

- Boreas BMVF Series

- KAITAIN JN Series

- KAITAIN JN 2-stager

- Kaitain JN Integrated

- Kaitain JN High Pressure

- Kaitain PMVF series

- Kaitain JN 0.3Mpa

- Kaitain JN 0.5Mpa

- Portable Air Compressor

- Kaishan KSCY diesel

- KAISHAN LGCY Diesel

- KAISHAN LGY Electrical

- KAISHAN LGCY 2 Stage compression Diesel

- KAISHAN KSDY Electrical

- KAISHAN ML Explosion-proof

- KAISHAN LGJY Mining

- KAISHAN LGN Series

- KAISHAN LGYT Mining

- Piston Air Compressor

- KAISHAN KA series

- KAISHAN KB Series

- KAISHAN KJ Series

- KAISHAN KS Series

- KAISHAN Mining Series

- Kaitec Screw Vacuum Pump

- High-speed Single-stage Centrifugal Blower

- Industrial Refrigeration Heat Pump Applied Screw Compressor

- Centrifugal Air Compressor

- Centrifugal Steam Compressor

- Centrifugal Refrigerating Compressor

- Gas Air Compressor

- ORC Screw Expansion Power Station

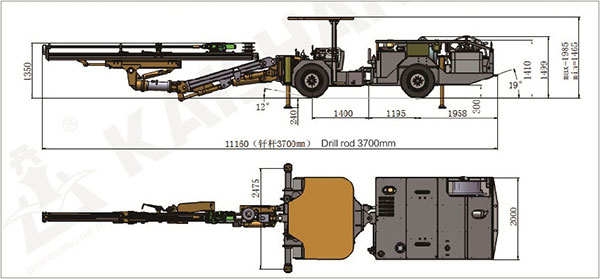

KJ212 Underground Mining Drill Rigs and Tunneling Jumbo can drill vertical, inclined and horizontal blast holes, designed exclusively for lower tunnel, with a passage section of 2.5m*1.5m, applicable to the tunnel with section of 3.5m*1.8m-5m*4.8m.

Its firm and reliable universal big boom has the best shape of section coverage, boosting the 360° overturn and automatic leveling of the beam for rapid and convenient borehole positioning. The big boom can also be used for lateral cross hole opening and anchor rod boring operations.

The arrangement of the jumbo ensures the good view of the operator.

Evenly-arranged and powerful 4-wheel drive hinge chassis ensures flexible, quick and safe driving in a narrow roadway.

The high-frequency percussion rock driller uses the cascaded piston to optimize the efficiency of shock wave transmission, raise the drilling speed, reduce clamping bit consumption and enhance the soundness of device.

The big space of operation and a series of automatic functions can help the driver to concentrate their attention to safe, rapid and accurate tunneling.

All its repair and maintenance parts have been protected well, and its repair and maintenance are easy.

Technical Parameters of KJ212 Underground Mining Drill Rigs and Tunneling Jumbo

Dimensions versus Weight |

|||

Length |

11160mm |

||

Width |

2000mm |

||

Height |

1465/1985mm |

||

Weight |

11000 kg |

||

Travelling speed, level |

10 km/h |

||

Climbing capacity |

20% (11°) |

||

Safety protection |

|||

Noise level |

<100 dB(A) |

||

Lifting safety roof |

Meet the requirements of FOPS and ROPS. |

||

Drilling system |

|||

Rock drilling |

1×HC50/R38 |

1×HC109/R38 |

1×HC95LM/R38 |

Impact power |

13kW |

18.8kW |

21KW |

Impact flow |

105L/min |

135L/min |

100-120L/min |

Impact pressure |

130bar |

135bar |

180bar |

Maximum rotation pressure |

150bar |

150bar |

210bar |

Frequency |

62 Hz |

47 Hz |

62Hz |

Torque |

325Nm |

780Nm |

764Nm |

Hole diameter |

Φ32-76mm |

Φ42-102mm |

Φ42-102mm |

Rolling of the propelling beam |

360° |

||

Feed extension |

1600mm |

||

Drill rod |

R38-H35-R32-3700 |

||

Model |

K 20 |

||

Form |

Automatic leveling |

||

Extension of drill boom |

None |

||

Electric Hydraulic pump unit |

|||

Electric motor |

45kW |

75kw | |

Impact- propelling-Boom |

Variable axial piston pump |

||

Rotation |

Gear pumps |

||

Filter precision |

10μ |

||

Hydraulic oil tank |

240L |

||

Hydraulic cooler |

Water cooler |

||

Working pressure |

380V |

||

Frequency |

50Hz |

||

Starting method |

Star - triangle |

||

Cable reel |

1×F440 |

||

Cable capacity of the reel |

100m |

80m | |

Outer diameter of cable |

Φ28mm |

Φ32mm | |

Specifications of cable |

3×35+3G6+2×1.5 |

3×50+3G6+2×1.5 | |

Air and water system |

|||

Air Compressor |

1×JN5 |

||

Capacity |

0.5m3/min |

||

Pressure |

6-8bar |

||

Device of shank lubrication |

Electrical pulse lubrication pump |

||

Air consumption for lubrication |

0.3m3/min |

||

Oil consumption for lubrication |

180-250g/h |

||

Water Pump |

1×CR3 |

1×CR5 | |

Power |

1.5kW |

5.5kw | |

Pump Capacity |

3m3/h |

6m3/h | |

Chassis |

|||

Diesel engine |

Cummins QSB3.9-C80-31 60kW/2200rpm |

||

Exhaust purification |

Exhaust catalyst |

||

Transmission |

Closed-wheel drive traveling system |

||

Swinging angle |

The rear axle swings for ±6° |

||

Tire |

300-15 |

||

Steering mechanism |

±35° articulated steering |

||

Travel brake |

Double loop hydraulic brake |

||

Parking brake |

Multi-disk wet brake for reducer |

||

Fuel tank |

30L |

||

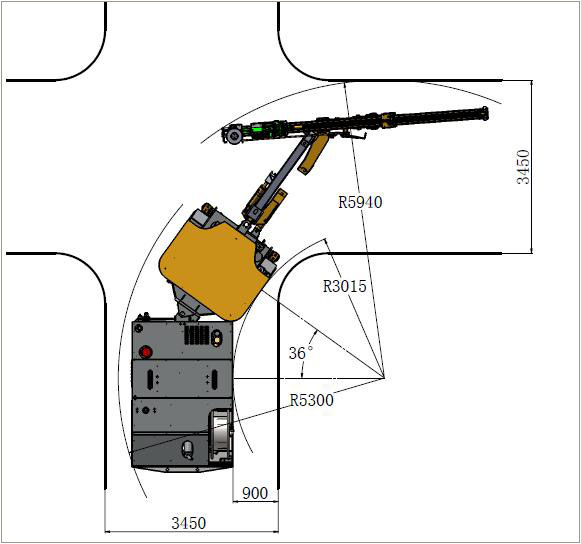

Turning Diagram

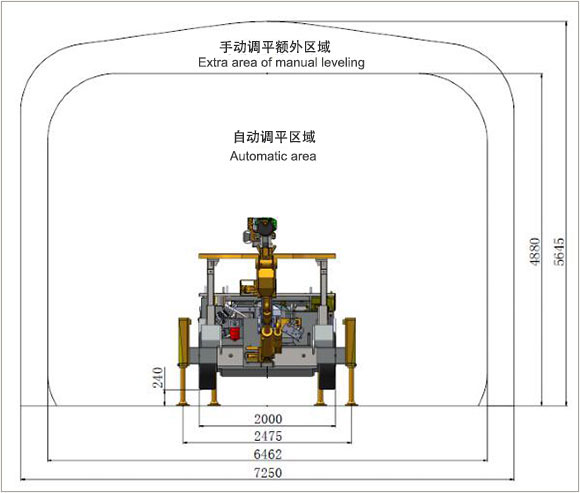

Coverage area

- Drill Rigs and Rock Drills

- TopHammer Drilling Rigs

- KL511 top hammer drilling rig

- KL510 top hammer drilling rig

- Tunneling jumbos(1 boom)

- KJ211 Tunneling jumbo

- KJ212 Tunneling jumbo

- KJ310 Tunneling jumbo

- KJ311 Tunneling jumbo

- KJ311 higher Tunneling jumbo

- KJ311 double Tunneling jumbo

- KJ311plateau Tunneling jumbo

- KJ311 Diesel Tunneling jumbo

- Face drill rigs(2 boom)

- KJ421 Tunneling jumbo

- KJ422 Tunneling jumbo

- Rock Bolting Rigs

- KM211 Rock Bolting Rig

- KM311 Rock Bolting Rig

- Tunneling DTH Rigs

- KS311 DTH Rig

- KSQ31 DTH Rig

- Tunneling Scaling Rigs

- KQ311 Scaling Rig

- Top Drive Drilling Rig

- KMD150 Anchoring Drill Rig

- Integrated DTH drilling rigs

- KT5C/YT5C DTH drilling rig

- KT6C DTH drilling rig

- KT7C DTH drilling rig

- KT9C DTH drilling rig

- ZT5 DTH drilling rig

- ZT10 DTH drilling rig

- KT11 DTH drilling rig

- KT12 DTH drilling rig

- KT15 DTH drilling rig

- KT20 DTH drilling rig

- KT25 DTH drilling rig

- KT30 DTH drilling rig

- KT20S DTH drilling rig

- RK60 DTH drilling rig

- Crawler DTH drilling rigs

- KG310 DTH drilling rig

- KG320 DTH drilling rig

- KG410 DTH drilling rig

- KG420 DTH drilling rig

- KG420S DTH drilling rig

- KG430 DTH drilling rig

- KG430S DTH drilling rig

- KG510 DTH drilling rig

- KG520 DTH drilling rig

- KG590 DTH drilling rig

- KG610 DTH drilling rig

- KG9 DTH drilling rig

- KG920BHIII DTH drilling rig

- KG726HIII DTH drilling rig

- KGH3AIII DTH drilling rig

- DTH Drilling rig

- Rock Drills and Jack Hammer

- Hand-held Rock Drill

- Air-leg Rock Drill

- Pneumatic Rock Drill

- Water Well Drilling Rig

- Crawler Water Well Drilling Rig

- Wagon Water Well Drilling rigs

- Core Drilling rigs

- Road Machinery

- Air Pick

- Auxiliary Equipment